|

As a bit of back story... the car

would very occasionally cut out suddenly and then be a bit

challenging to get started, but then be fine again. Then there

was an incident where I'd been for a long drive on a hot day and

on the way back I called into a hardware store and when I came

to leave the car wouldn't start - it would just turn-over

without firing. After a few hours I picked up a replacement

distributor cap and this seemed to get the car started and I

drove home without further incident.

Some months later I set off for a

car show but within only a couple of miles the car did its

cutting out thing. I got it started again and continued on, but

it didn't seem right so I took it easy. Sure enough though, as I

was getting past a lorry on a dual carriageway, the engine cut

out and I had to manoeuvre off into a lay-bay. Here the car

wouldn't start again until after half an hour, in a last-ditch

attempt, I sprayed electrical contact cleaner onto the

Electro-spark module under the ignition cap. This got the car

started but it wasn't running right so I limped it home.

Now I wrongly assumed the

Electro-spark module or ignition circuit was at fault, but

trying a new module made no difference; once the car warmed up

it would run rough. By this point I finally discovered the

coolant was low and things had been overheating. I replaced the

hoses, water pump and coolant, to no effect. The verdict?

Headgasket.

I got myself a compression

testing kit and this indicated that two cylinders had ok

compression, while two others were low, but they weren't

adjacent cylinders, so the result, whist not good, was odd. To

investigate further I now got hold of a bore scope to inspect

each cylinder. Annoyingly I was sent a lower spec one, but I

used it as best I could before sending it back for a refund.

From what I could see from the images the cylinder walls looked

ok (no heavy scoring), but some of the piston tops looked

pitted, and there was also a bit of something down the side of

one.

The plan: remove the head

and do whatever work is revealed beyond the headgasket (perhaps

piston rings, or more besides).

With the car now in its garage I

got to work first sorted out the lighting in

the room because the strip lights had been positioned before I'd

envisioned I would be turning the room back into a garage and

the bonnet simply cast a shadow over the engine bay.

The nearest light is a new addition, the others

are of no use, but they can be switched off independently.

Having said that, the Hayne's

Manual includes "removing the bonnet" as one of the steps for

removing the head of the engine, but I'm suspecting that's not

necessary and I don't like the idea of having to lift it off the

car (I would need help with that) and re-aligning it later.

With the lighting improved, I

have now started slowly picking away at the car; coolant drained

(again), radiator out (again), timing belt cover removed

(again), a washer dropped down behind the bottom pulley...

(bugger)

Also on the to-do list is the crank case oil seal

that's had a slight leak for a while...

I'm also addressing other

things along the way; I removed the front grille because it had

a break in the plastic and keeps getting broken from leaning

over it. With it removed some rust spots are being treated.

I fashioned a suitably sized

and sturdy block of wood and knocked it into place to wedge the

pulley. It was close but it held enough for me to get the nut

undone.

Then the pulley pulled off with the aid of a bit

of leverage.

There's that pesky washer, sitting down between

the belt and the casing. It was actually a rubber washer so

wouldn't have been detrimental, but I actually thought it was a

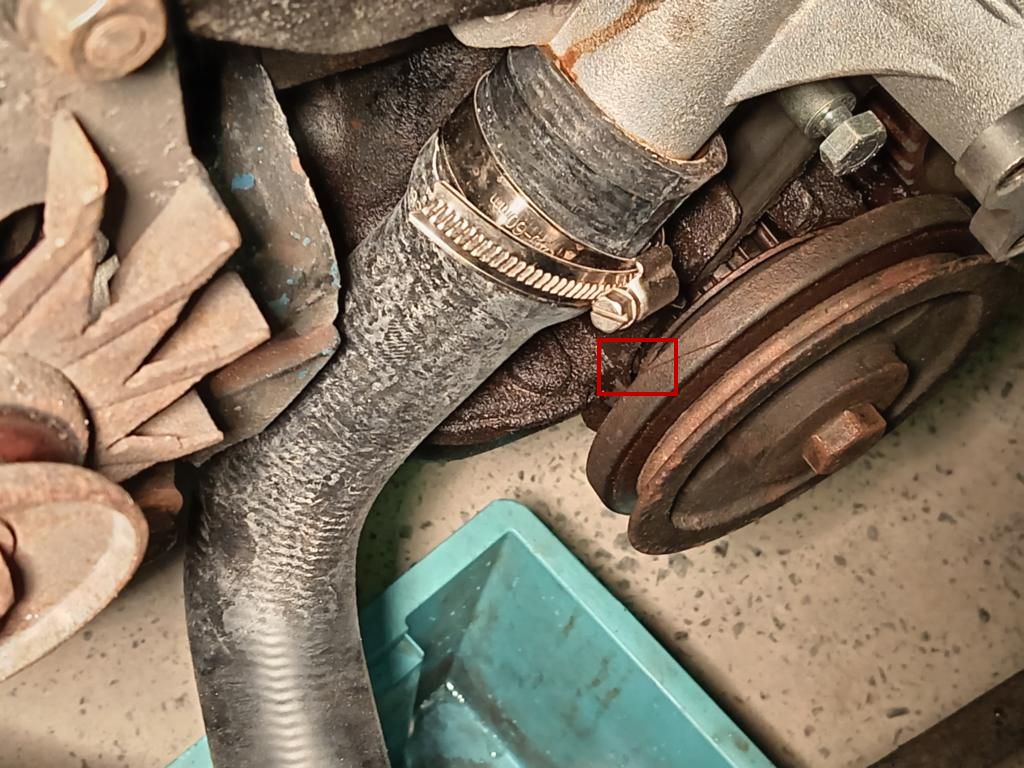

metal one. Moving on, I

re-removed the shiny new water pump (below). One thing I haven't

been sure about is that the alternator clamp is held to a bolt

that fastens the pump to the engine, whereas there is what seems

to be a proper mounting point for it below, but it was never

like that with the original pump and would it require a

different bolt, and a nut, which I don't have. Also, there was a

slight leak from the pump's fresh gasket (which I knew

about) because I believe I was supposed to oil the cardboard

gasket before installing(?) and I failed to do that. The gasket

needs replacing though and there are some, what are claimed to

be, "uprated" gaskets. The water pump bolts have a very low

tourque settings and since one of the original ones snapped when

I first removed the original pump I was very cautious not to

over-tighten them to mitigate leaks (they didn't feel tight

enough though).

|